Some of the applications Penguin Programs has developed over the years:

-

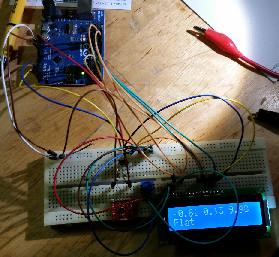

Arduino

Example of Arduino project, using the Arduino Uno, a MMA8452Q accelerometer and a simple 16x2 LCD for readout. The system is used for calibration of another device measuring acceleration.

-

PicoCom and Window CE6

Project using the PicoCom A5, two Ethernet interfaces, a 25LC256 256K SPI Bus Serial EEPROM to store configuration data, a EDT screen with an FT5x06 Capacitive Touch Panel Controller and a MCP23S08 8-Bit I/O Expander controlling a DIP switch for hardware configuration.

Development system was Visual Studio 2008, using VB.NET.

-

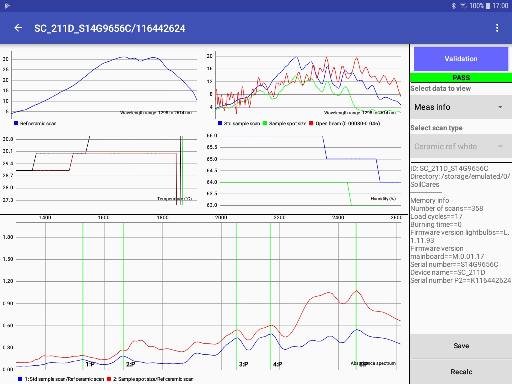

Android

This Android app is used for quality inspection of the AgroCares scanner. (see https://www.agrocares.com/scanners/).

The scanner is controlled from the app using Bluetooth. The app allows the user to perform a number of different, well defined scans, retrieves the resulting scan data (called interferograms) and stores it on the Android device. Finally, spectra are calculated from the scan data and validated (using a Java library supplied by AgroCares). The image above shows the result screen, showing some of the spectra and the validation result.

Development system is (this app is still being actively developed) Android Studio.

-

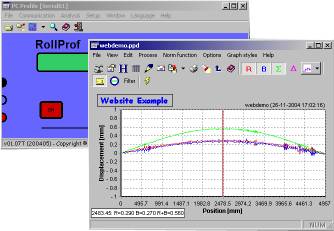

PC Profile (see www.rollprof.com)

Communicates through RS-232 (but also TCP/IP by using a converter) with a measurement instrument called the Rollprof. The Rollprof allows the user to make measurements of roller profiles. The application lets the user prepare measurements, download programs to the Rollprof, upload and analyse measured data.

In a later version of the Rollprof device, Bluetooth and USB have been added, both of which are supported by the PC Profile program. The picture above shows the old Rollprof, for the new version, the 3T, see the Rollprof website.

-

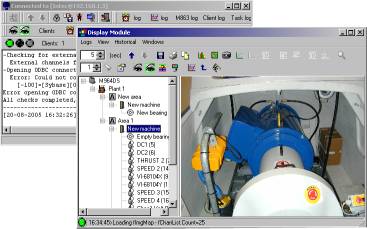

M964/DMxMgr Condition Monitoring System (Note: Discontinued product.)

A 24/7 system of applications. One application is used to configure the condition monitoring system. Once the configuration has been completed, monitoring is started through the master server application. This master server executes slave servers as needed, generally one slave per instrument. A slave can be one the same computer as the master or on any computer within the network. The monitoring result can be followed from anywhere in the network by using the viewer application.

-

SHORTEMP

This program calculates the resulting hardness and other material parameters for a steel bearing after undergoing heat treatment, both hardening and tempering. The program is used to fine tune "short time" heat treatment at a higher temperature, something which is desirable since it leads to an increase in production. However, using a higher temperature means that the risk of the process going wrong also increases. It is therefore of greate importance to understand and to model the process which is exactly where SHORTEMP comes in.

-

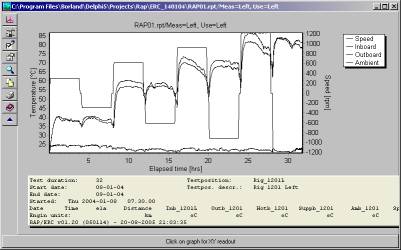

RAP (Railway Analysis Program)

When testing components for railways, measurements are done for a long time (several days) in a specially equipped rig. The result of such a test is a massive amount of data, in many cases several ten thousands of data points. This data has to be analysed according to strict rules, resulting in a final PASS or FAIL verdict.

The analysis, among other things, compares temperatures in time, looking for temperature differences but also differences between left and right side of the train axlebox. For each difference, there is a limit which may not be exceeded. This analysis is what RAP does. Next to the standard analysis, RAP supplies a number of tools to let the user visualise the data, something which is quite difficult considering the amount of data.

-

ASP.NET - Heat Treatment Toolbox

An ASP.NET application developed for SKF, providing the material people inside the company with some easy accessible standard tools. The picture shows one of the modules, calculation of Martensite Hardening Response, i.e. what the result is of martensitic heat treatment.